×

YÜKLE

2A Mühendislik

Google Play'de - ÜCRETSİZ

TRH – TRS

POMPETRAVAINI is one of the leading worldwide manufacturers of liquid ring vacuum Pumps with single stage TRS and two stages TRH pump series. With the experience acqurid through decades of engineering research, continual investments in the latest technological advanced machinery, and sound mechanical know-how, Pompetravaini’s product is today synonytion and maximum reliability.

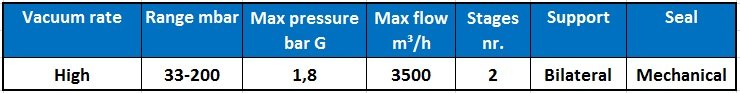

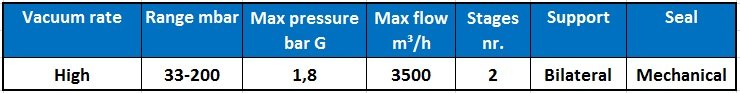

Pumps series TRH; Capacity = 3 – 3500 m3/h, Vacuum = 33 – 200 mbar

Pumps series TRS; Capacity = 10 – 3500 m3/h, Vacuum = 200 – 900 mbar

APLICATIONS

FEATURES

QUALITY

Designed and manufactured under the ISO 9001 standartds, every components is guaranteed for the selected materials, wokmanship and performance through scrupulous inspections during production stages and final testing of finished product.

FEWER COMPONENTS

Through engineered disegn innovations and co-operation with the finest technologically advanced foundries, the Pumps are manufactured with less componants than typically required. Fewer parts add to the rigidity and toughness of the Pumps, they are easier to assemble and Maintenance is greatly facilitated.

COMPACT DIMANSIONS

The conventional stuffing boxes construction is eliminated with the Pompetravaini standard design. The shaft lenght is greatly reduced thus eliminating the pontential ganger for shaft deflections and vibrations to the mechanical seals which would increase seals and bearing wear.

STANDARD MECHANICAL SEALS

In keeping pace with today technology, Pompetravaini has standarized all pumps to accept unified mechanical seals to DIN 24960 standards. Also available upon request, are constructions with double mechanical seals (tandem or back to back) or cartridge type mechanical seals.

LARGE SELECTION OF MATERIALS

In addition to the standard materials, Pompetravaini Pumps are also available with special exotic materials such as Ni-Resist D2B, Hastelloy B or C, Uranus B6, etc. To meet specific requirments.

MECHANICAL RELIABILITY

With the simple design of liquid ring Pumps there are no reciprocating parts, no valves or sliding vanes. The impeller is the only rotating components with no metal-to-metal contact. Pump operation is therefore with minimal wear, vibrations free and noise levels are greatly reduced.

LIQUID HANDLING CAPABILITY

Pumps are capable of handling even high volumes of vapours, condensables and liquids, without detrimental consequences to their performance or their mechanical reliability. Pump service liquid can be water or other liquids such as oils, solvents, etc. To satisfy almost any process requirments.

DISCHARGE OIL FREE AIR

With clean water as pump service liquid, the aspirated air (or gas) is “washed clean” within the pump. Contrary to other types of vacuum Pumps the discharged air is, therefore, completely free of any oils, carbon or plastic particles.

MOUNTING TO B3 OR B5 MOTORS

Pompetravaini standard design may be base-mounted coupled to motors type B3. Pumps up to 30 KW can also be close coupled to motors type B5 utilizing specially Designed attachment flange. This close-coupled arrangment allows utilization of standard readily available Electric motors, eliminates lenghty alignment procedures and costly breakdowns associated with misalignments. Overall dimensions are reduced and engineered baseplates are no longer required.

PRESSURE TO LESS THAN 33 MBAR

Liquid ring vacuum Pumps, type TRH in series with devices such as ejector and/or vacuum boosters can operate at pressure lower then 1 mbar.

Double or single stage liquid ring vacuum pumps

Capacity to 3500 m3/h, max vacuum 33 mbar

Technical Specifications

Double or single stage liquid ring vacuum pumps